About This Quiz

When cars were invented over a hundred years ago, their engines were certainly not as complex as they are today. And they definitely did not have computers which made sure that everything ran as smoothly as possible at all times like modern engines do.Â

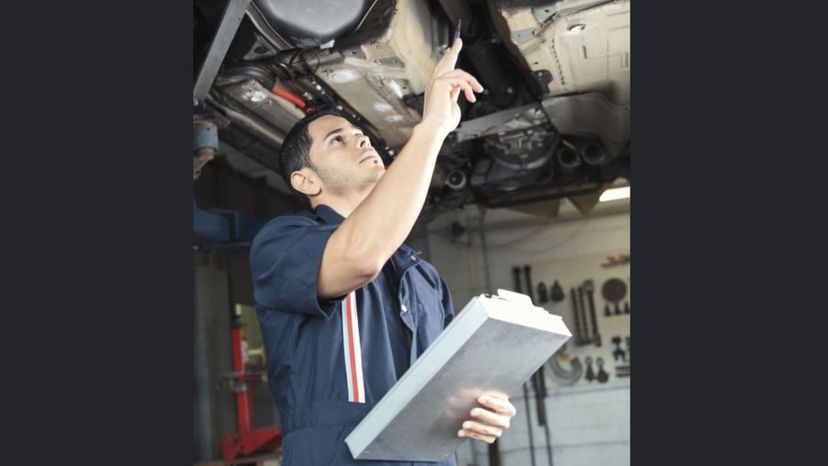

In fact, if your car has a problem, the first thing an auto mechanic is likely to do is plug in his laptop to see if he can isolate where it originates from. But that's not the only tool he is going to use while working on your vehicle. While modern engines are a far cry from those of yesteryear, some tools needed to work on them remain the same.

Engines still need to be bolted together, so you're going to need sockets, wrenches, screwdrivers and many more loosening and tightening tools. A good hammer also comes in handy when something needs a light tap, such as a stubborn bolt that won't turn. There are also a plethora of gauges and measuring tools that auto shops use on a daily basis. The list goes on and on.

Now the question is, do you think you could identify a range of tools that are used in the auto shop?

Let's put your knowledge to the test!

Although you think you might never need pliers when working on an engine, you will be surprised the number of times you wish you had one if you didn't have one in your toolbox.

A flashlight is crucial while working on the innards of a car, be it the engine, suspension or practically anywhere. And to keep your hands free, use a flashlight that straps to your head. Or employ an apprentice!

No self-respecting workshop is going to attempt any engine work without a number of wrenches. Available in a number of sizes, these are the easiest way to tighten or loosen nuts. An adjustable wrench where you can set the size is also known as a monkey spanner.

Advertisement

Ohm meters are a necessity, especially for any auto electrical work that you might need to carry out. Ohm meters essentially measure electrical resistance.

These special tools are necessary if you would like to create screw threads. This might be necessary when overhauling an engine.

This tool is particularly useful when working on the valves of an engine. It helps to determine the right height for both the spring and the valve in their chambers. A micrometer is needed for exact measurements. As measurements will differ between cylinders, use the shortest measurement taken.

Advertisement

Sometimes studs can be damaged, making it impossible to remove the bolt off the thread or perhaps the bolt has broken off and the stud needs to be removed to insert a new one. Luckily, in times like this, a stud removal tool is just what you need to get the job done.

When working on a make of vehicle, having the repair manual can help immensely. If your car dealer does not supply you with one for your vehicle, finding one online is easy.

A hammer? To work on an engine? Yes, you never know when it might come in necessary. For example, a jammed starter motor might just need a gentle tap from a hammer to become unstuck.

Advertisement

A socket set serves much the same purpose as a wrench but here, you place the socket over the nut and use a socket wrench to tighten or loosen. The advantage here is that it can be used to work on hard-to-reach nuts thanks to extender bars.

Allen keys come in an array of sizes and are made to fit small hexagonal-shaped head. Allen keys are sometimes called hex keys.

A good screwdriver set is never out of place in a workshop and a necessity when working on an engine of any kind. Make sure you have a range of different kinds from regular, to Philips to Robertson just to name a few.

Advertisement

When rebuilding an engine, having the correct length push rods is critical. This tool helps ensure that this happens. Best of all, they are relatively inexpensive.

Sometimes called a valve lash wrench, this is used when adjusting the valves on an engine. Sometimes this tool also comes with a built-in torque wrench.

This is not a tool that everyone will have in their workshop, but if you plan on rebuilding engines on a regular basis, it is a necessity. This adjustable tool holds and installs the different-sized cam bearings.

Advertisement

Many oil filters are turned into place by hand and then tightened using an oil filter wrench. These also help remove older filters that might have become stuck in place due to the heat of the engine over time.

This tool is similar to a regular wrench except in the fact that it applies a precise torque to the fastener or bolt you are tightening. This prevents over tightening. The torque wrench was invented in 1918 by Conrad Bahr.

Used in conjunction with a valve checking spring kit, this micrometer helps determine the height of the valves in the engine.

Advertisement

No self-respecting workshop will be without a pulley, hoist and lift. Engines are heavy and three tools make it possible to not only remove them but replace them back into the chassis with minimal fuss.

A caliper is used to measure the distance between from opposing sides of a particular object. They have any number of uses when working on a car engine.

Similar to an Allen key, a Torx bit will fit a specially shaped head on a range of bolts. They are easily identified by their six-point star shape.

Advertisement

All modern cars have computers that run pretty much everything in the vehicle. When something goes wrong with this computer, having one of these gadgets can not only help identify the problem easier but can also fix it in many cases.

This is used for working on the crankshaft particularly and allows for the rotation of the crankshaft with the damper removed. It works with a normal ratchet.

No, it's not something you need for Halloween, but a simple flat board with wheels. Lie on this and you can scoot anywhere you need to while checking under a vehicle. This is particularly useful if you do not have a vehicle lift.

Advertisement

Is there an auto doctor in the house? These stethoscopes included a long point probe, perfect for placing at points throughout the engine to listen for problematic sounds.

A hydraulic floor jack is the perfect way to quickly raise a car from one side. It is a far better option than a manual jack and gets the job done in seconds. It does cost a little more, however!

A nut splitter is a great way to loosen nuts, screws or bolts that have become tricky to turn or loosen. It the nut still won't loosen, the splitter can be tightened until the nut breaks in half. Then you simply need to replace it.

Advertisement

Flexible sockets allow you to get into hard-to-reach places, attach a socket to a nut or bolt and remove it with ease. Couple it with an extender and you will have no problem loosening anything.

Zip ties are a great way to keep pipes, wires and leads together. For example, keep the high tension leads between the spark plugs and distributor cap neat and tidy by using zip ties to bind them together.

A socket extension allows you to reach in difficult areas within the engine to loosen bolts or nuts. This makes it far easier to loosen these fasteners than having to struggle with a normal socket tool.

Advertisement

Not sure if a particular circuit is working within the electrical system of your car? A circuit test will tell whether it is or not .

Car lifts help raise the car off the ground and allow mechanics to check underneath the engine with ease. They make life so much easier than sliding around on your back or on a creeper under the car.

Also known as an air gun, this uses compressed air to spin and is the quickest way to attach or remove nuts. If you have one, you too can change tires as fast as they do in IndyCar racing.

Advertisement

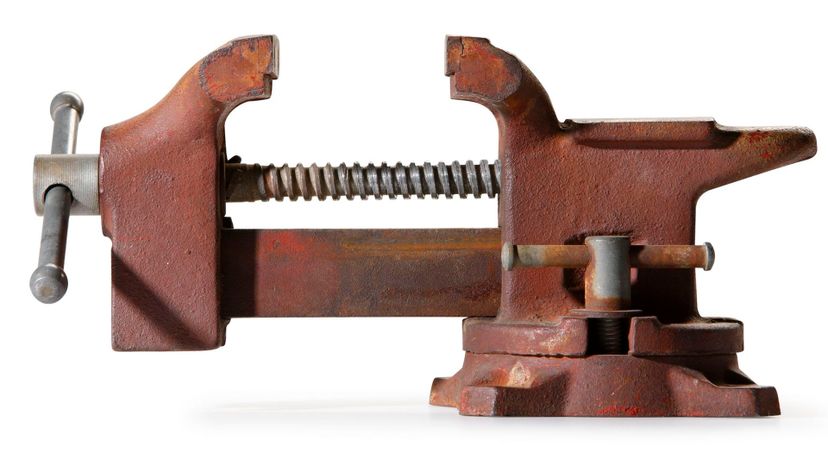

Every good workshop needs a vise. You never know when you need to grip something tightly to be able to work on it without worrying that it might come loose and fall to the ground.

Drip pans help keep the floor of your workshop clean. Engines are filled with various fluids and when taking them apart, these will drip onto the floor. A drip pan helps you to keep control of the mess.

Engine parts, particularly on old engine rebuilds need to be cleaned. The best way to do this is by simply soaking them and then cleaning them in a part washing container.

Advertisement

Struggling with a flat battery? A jumper pack will get it started first time and the charger will ensure that you get a charge back into it so you won't need to jump it again.

Engines are heavy. When removed from a vehicle, they need somewhere to stand without the chance of falling and getting damaged. An engine stand will do the job perfectly.

A good set of cleaning brushes can be used throughout your workshop on a number of different things, including keeping an engine shiny clean.

Advertisement

While working on an engine, the crankshaft will need to be tuned and adjusted many times. This socket does the job for you without any fear of damaging the crankshaft itself. This is all done when the harmonic balancer, or dampener, is removed.